NC machines have paved the way for CNC machines, making them the basis for where technology has reached today. They are known to be the initial evolution of conventional machines, making the way for what we have today - the advanced machines for precision cutting.

In a generic sense, NC machines are distributed into three kinds -

1. Traditional Numeric Machines

They are the very first evolution of conventional machines, run on a tape reader system. A tape reader system is where you have to punch the operation you want to perform and the NC machine does the job for you.

2. Computer Numerical Control

These evolved to overcome the limitations of NC machines, CNCs are more commonly used in today’s world. NC machines, as mentioned earlier, run on the tape reader system. The continuous wear and tear of these tapes frequently demand the operator to punch on new tape in order to finish the operation. CNCs completely discard this limitation; with its computer-based file generation, CNCs can store program which was written by the usage of G-Codes and M-Codes.

3. Distributed Numerical Control

DNC is closely similar to computer numerical control. The only difference is that distributed numerical control operators operate with the help of a remote computer. This remote computer controls the number of operations that a particular number of machines can perform at a given time. In simple terms, a central remote computer or DNC communicates and controls the local CNCs for all the operations.

Types of CNC machines

1. CNC Milling Machines

One of the most common CNC machine types, the CNC milling machine rotates the cutting tools around a stationary material. Components manufactured on these machines are typically square or rectangular. The machine compatibly reads the standardized programming language i.e. G-code. The computer code instructs the tools on the machinery to turn, drill, mill, and tap in order to produce a highly accurate modelled piece. Most CNC milling machines are available from 3-axis to 6-axis configurations, to be chosen depending on the project requirement.

2. CNC Router Machines

Similar to the CNC milling machines but more apt for softer materials, the CNC router machine is another one of the more preferred options. It is typically used for engraving in softer materials such as wood, aluminum, composites, plastic, foam, and even steel. As against a CNC milling machine, the CNC router is preferred for projects that do not require higher accuracy. These machines help complete projects faster and more efficiently than handheld routers and are generally cheaper than the CNC milling machines. The CNC routers are available from 3-axis to 6-axis configurations.

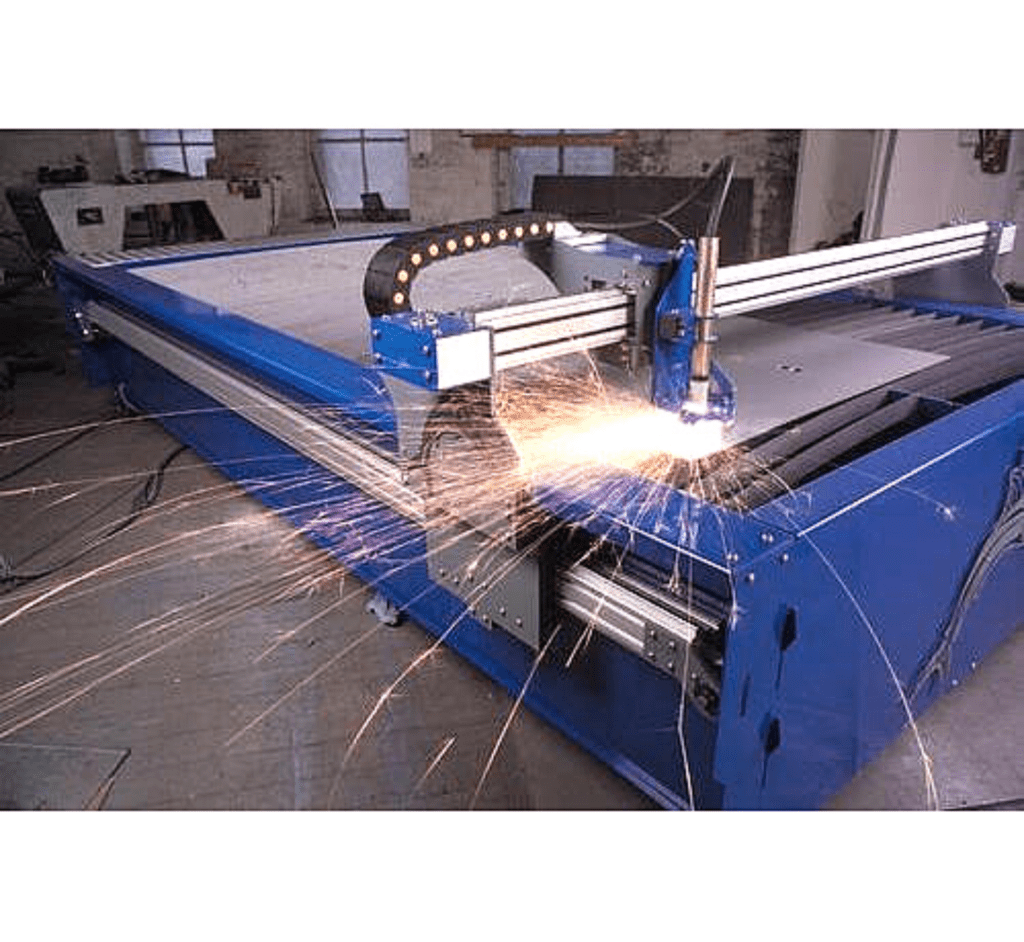

3. CNC Plasma Cutting Machines

A special addition to the standard CNC machines, CNC plasma cutting machines use a high-powered plasma (electronically-ionized gas) torch to cut materials. A standard handheld, gas-powered torch used for wielding goes up to 10,000 degrees Fahrenheit, whereas a plasma torch can achieve temperatures up to 50,000 degrees Fahrenheit. All this type of CNC machine needs is a compatible material to work with, meaning the material being cut must be electrically conductive. The common materials that are apt for plasma cutting are steel, stainless steel, aluminum, brass, and copper.

4. CNC Lathes and Turning Machines

Characterized by their ability to rotate or turn materials during operations, this CNC machine is a boon to manual precision cutting as they offer more clean cuts. They engage fewer axes compared to CNC milling machines, making them smaller and more compact in size.

5. CNC Electric Discharge Machine

EDM creates a cut or a shape onto a material by using electrical discharges, commonly known as sparks. There are two electrodes involved in the process; all you need to do is place the material in between and the machine calculates the rest. After creating the desired cut or shape, the material is flushed with a particular kind of liquid for more precision.

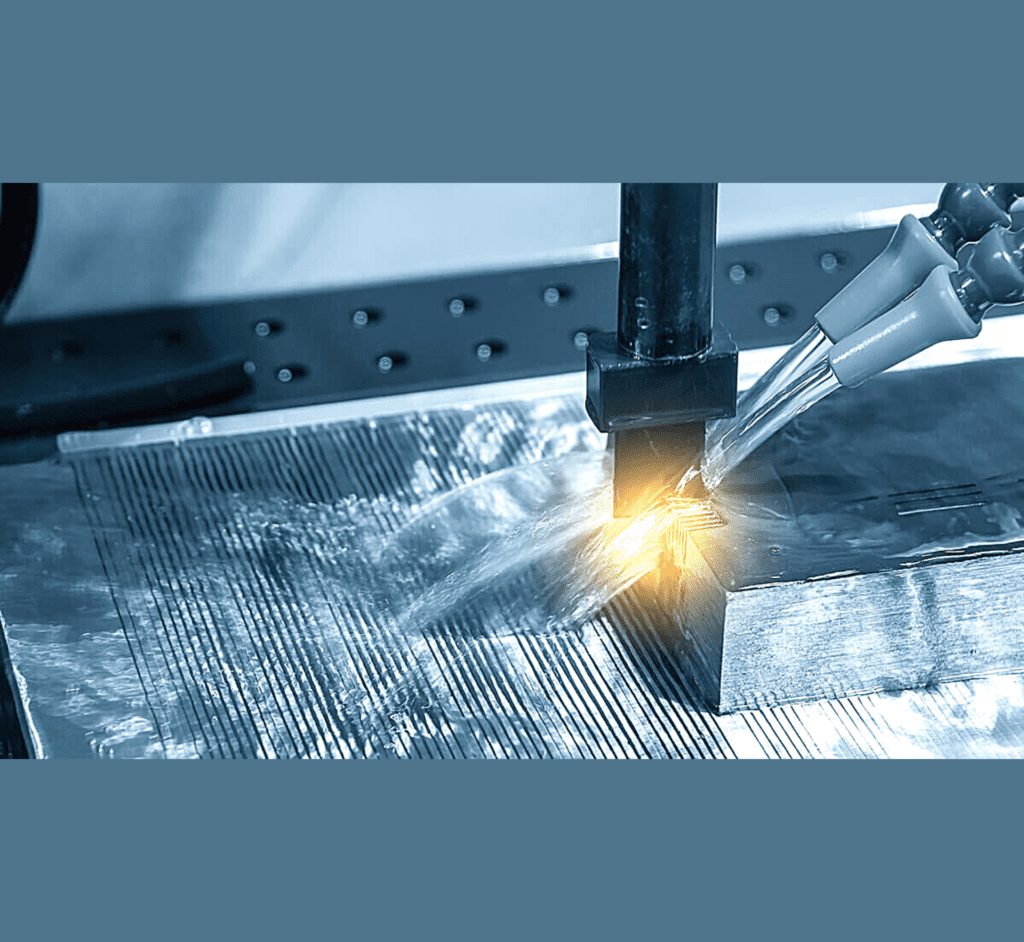

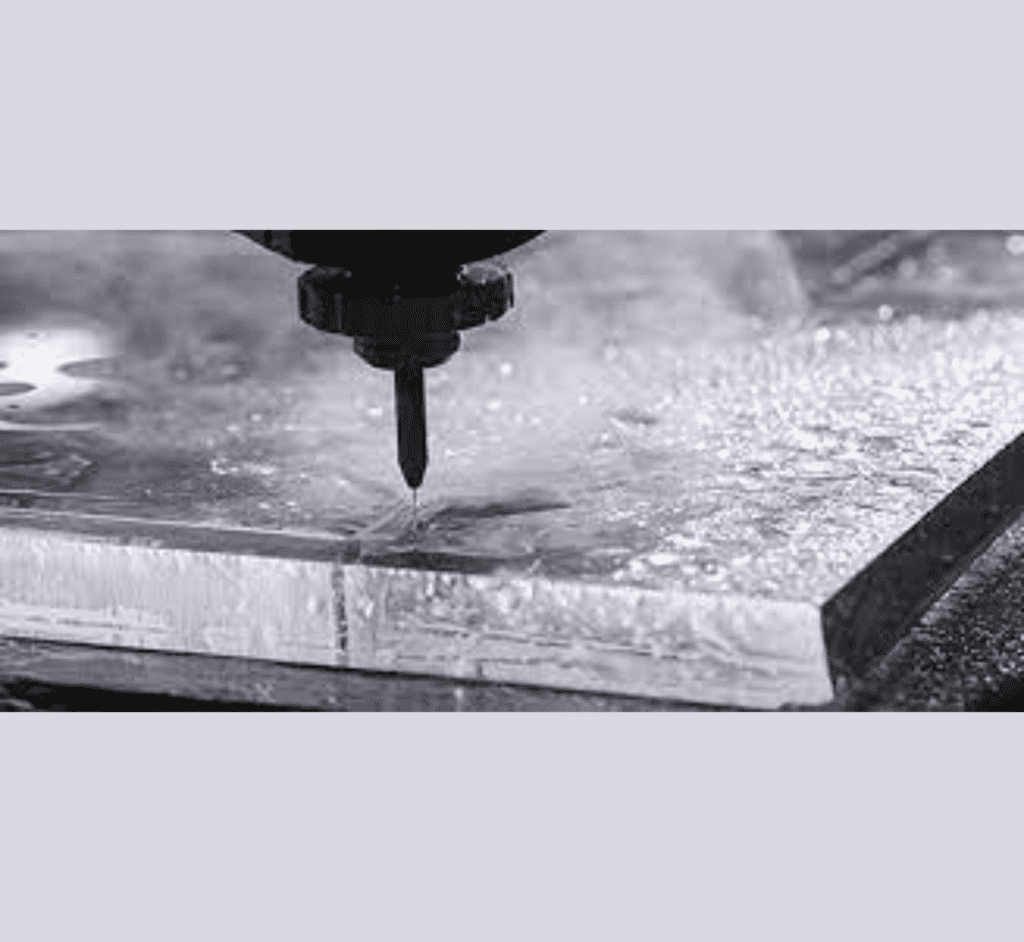

6. CNC Waterjet Cutting

As the name suggests, a CNC waterjet machine uses high-pressure water jets to cut through a particular material. For softer materials like wood and rubber, this machine uses water alone, but in case you need to cut through harder materials, the machine mixes abrasive substances such as garnet or aluminum oxide with water for desired results.

Conclusion:

While the advancements in technology have given mankind enough resources, you need to be very particular about the application of these machines. In simple terms, you need to employ all the right skills in order to fully encompass what these machines offer, to gain the best out of your investment.